Product Description

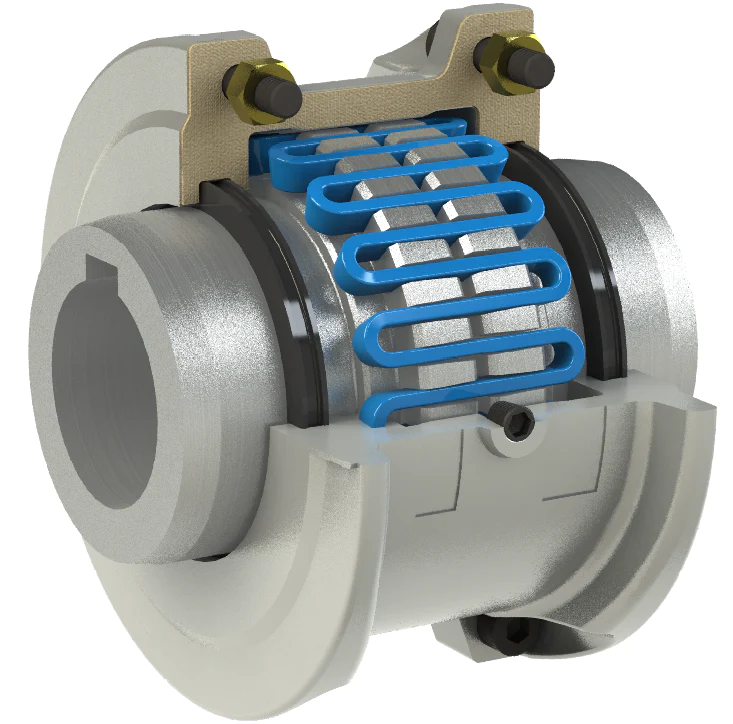

JS700 Series High Speed Grid Coupling

♦Description

Grid Coupling is widely used in metallurgy, mining, lifting, transportation, petroleum, chemical, ships, textile, light industry, agricultural machinery, printing machines and pumps, fans, compressors, machine tools and other mechanical equipment and industry shaft transmission.

Feature:

1.The serpentine spring as the elastic element, the elastic strong at the same time, greatly improves the grid coupling torque, widely used in heavy machinery and general machinery. The serpentine spring special technology department, has long service life, allowing higher speed, has good ability to compensate in the axial, radial and angle

2.High transmission efficiency, start safety. Transmission efficiency of up to 99.47%, short-time overload capacity is 2 times the rated torque, operation safety.

3.Simple structure, convenient assembly and disassembly, long service life

4.Damping effect is good to avoid the resonance.

♦Basic Parameter and Main Dimension

| Model | Nominal Torque N.m |

Speed r/min |

Y,Z Bore d1,d2 |

D | B | A | E | N | L | M | P | J | Clearance (K) | Oil injection Kg |

No bore mass Kg |

|||

| Max | Min | Min | Standard | Max | ||||||||||||||

| JS702 | 125 | 10000 | 35 | 14 | 120 | 107 | 50 | 80 | 80 | 52 | 78 | 27 | 50 | 1.5 | 3 | 5 | 0.03 | 8 |

| JS704 | 400 | 9000 | 48 | 14 | 160 | 127 | 65 | 105 | 105 | 62 | 95 | 36 | 60 | 1.5 | 3 | 5 | 0.03 | 11 |

| JS706 | 900 | 8200 | 65 | 19 | 185 | 167 | 90 | 125 | 130 | 82 | 105 | 50 | 65 | 1.5 | 3 | 5 | 0.06 | 12 |

| JS707 | 1800 | 7100 | 75 | 28 | 218 | 228 | 105 | 150 | 156 | 112 | 135 | 52 | 86 | 1.5 | 4 | 6.5 | 0.06 | 15 |

| JS708 | 3150 | 6000 | 85 | 28 | 245 | 228 | 125 | 180 | 175 | 112 | 145 | 58 | 92 | 1.5 | 4 | 6.5 | 0.09 | 20 |

| JS709 | 5600 | 4900 | 100 | 42 | 286 | 290 | 140 | 210 | 208 | 142 | 180 | 70 | 118 | 1.5 | 6 | 10 | 0.09 | 25 |

| JS710 | 8000 | 4500 | 110 | 42 | 325 | 290 | 160 | 245 | 230 | 142 | 190 | 74 | 125 | 1.5 | 6 | 10 | 0.17 | 33 |

| JS711 | 12500 | 4000 | 125 | 60 | 330 | 290 | 180 | 180 | 258 | 142 | 220 | 85 | 150 | 1.5 | 6 | 13 | 0.26 | 57 |

| JS712 | 18000 | 3600 | 150 | 70 | 365 | 351 | 220 | 220 | 295 | 172 | 225 | 95 | 150 | 1.5 | 6 | 13 | 0.43 | 80 |

| JS713 | 26000 | 3300 | 180 | 70 | 420 | 351 | 255 | 255 | 335 | 172 | 235 | 115 | 156 | 1.5 | 6 | 13 | 0.51 | 97 |

Note: The selection method and marking method of JS700 high speed snake spring coupling are the same as that of JS100.

♦Other Products List

| Transmission Machinery Parts Name |

Model |

| Universal Coupling | WS,WSD,WSP |

| Cardan Shaft | SWC,SWP,SWZ |

| Tooth Coupling | CL,CLZ,GCLD,GIICL, GICL,NGCL,GGCL,GCLK |

| Disc Coupling | JMI,JMIJ,JMII,JMIIJ |

| High Flexible Coupling | LM |

| Chain Coupling | GL |

| Jaw Coupling | LT |

| Grid Coupling | JS |

♦Our Company

HangZhou CHINAMFG Machinery Manufacturing Co., Ltd. is a high-tech enterprise specializing in the design and manufacture of various types of coupling. There are 86 employees in our company, including 2 senior engineers and no fewer than 20 mechanical design and manufacture, heat treatment, welding, and other professionals.

Advanced and reasonable process, complete detection means. Our company actively introduces foreign advanced technology and equipment, on the basis of the condition, we make full use of the advantage and do more research and innovation. Strict to high quality and operate strictly in accordance with the ISO9000 quality certification system standard mode.

Our company supplies different kinds of products. High quality and reasonable price. We stick to the principle of “quality first, service first, continuous improvement and innovation to meet the customers” for the management and “zero defect, zero complaints” as the quality objective.

♦Our Services

1.Design Services

Our design team has experience in cardan shaft relating to product design and development. If you have any needs for your new product or wish to make further improvements, we are here to offer our support.

2.Product Services

Raw materials → Cutting → Forging →Rough machining →Shot blasting →Heat treatment →Testing →Fashioning →Cleaning→ Assembly→ Packing→ Shipping

3.Samples Procedure

We could develop the sample according to your requirement and amend the sample constantly to meet your need.

4.Research & Development

We usually research the new needs of the market and develop the new model when there is new cars in the market.

5.Quality Control

Every step should be special test by Professional Staff according to the standard of ISO9001 and TS16949.

♦FAQ

Q 1: Are you trading company or manufacturer?

A: We are a professional manufacturer specializing in manufacturing various series of couplings.

Q 2: Can you do OEM?

Yes, we can. We can do OEM & ODM for all the customers with customized artworks of PDF or AI format.

Q 3: How long is your delivery time?

Generally it is 20-30 days if the goods are not in stock. It is according to quantity.

Q 4: Do you provide samples? Is it free or extra?

Yes, we could offer the sample but not for free.Actually we have a very good price principle, when you make the bulk order then cost of sample will be deducted.

Q 5: How long is your warranty?

A: Our Warranty is 12 months under normal circumstance.

Q 6: What is the MOQ?

A: Usually our MOQ is 1 pcs.

Q 7: Do you have inspection procedures for coupling?

A: 100% self-inspection before packing.

Q 8: Can I have a visit to your factory before the order?

A: Sure,welcome to visit our factory.

Q 9: What’s your payment?

A: T/T.

♦Contact Us

Web: huadingcoupling

Add: No.11 HangZhou Road,Chengnan park,HangZhou City,ZheJiang Province,China

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Can Motor Couplings Compensate for Angular, Parallel, and Axial Misalignments?

Yes, motor couplings are designed to compensate for certain degrees of angular, parallel, and axial misalignments between the motor and driven shafts.

Angular Misalignment: Motor couplings can accommodate angular misalignment, which is the deviation in angle between the motor shaft and the driven shaft. This misalignment occurs when the two shafts are not perfectly collinear. Flexible couplings, such as elastomeric or grid couplings, can provide higher angular misalignment capabilities compared to rigid couplings.

Parallel Misalignment: Parallel misalignment refers to the lateral offset between the motor shaft and the driven shaft. Motor couplings can compensate for this misalignment to a certain extent. Flexible couplings with torsional flexibility, such as elastomeric or grid couplings, are better suited to handle parallel misalignment compared to rigid couplings.

Axial Misalignment: Axial misalignment is the displacement along the axis of the motor and driven shafts. Motor couplings can also accommodate axial misalignment to some degree. The ability to handle axial misalignment varies depending on the coupling type and design.

While motor couplings can compensate for misalignments, it is essential to ensure that the misalignment does not exceed the coupling’s specified limits. Excessive misalignment beyond the coupling’s capabilities can lead to premature wear, increased stress on the coupling and connected equipment, and potential coupling failure.

Choosing the appropriate coupling type and size based on the specific misalignment requirements of the application is crucial for optimal performance, reliability, and longevity of the motor coupling in mechanical power transmission systems.

Do motor couplings require regular maintenance, and if so, what does it involve?

Motor couplings do require regular maintenance to ensure their proper functioning and to extend their lifespan. The maintenance procedures typically involve the following steps:

- Inspection: Regular visual inspections are necessary to check for signs of wear, damage, or misalignment. Inspect the coupling for any cracks, corrosion, or unusual vibrations.

- Lubrication: Some motor couplings, especially flexible and universal couplings, require proper lubrication to reduce friction and prevent premature failure. Follow the manufacturer’s recommendations for the type and frequency of lubrication.

- Tightening: Check and tighten the coupling’s fasteners regularly to prevent any loosening that might occur due to continuous operation or vibrations.

- Alignment: Ensuring proper alignment between the motor and driven load is essential for motor couplings. Misalignment can lead to increased stress and wear on the coupling, causing it to fail prematurely.

- Replacement: Over time, motor couplings may experience wear and tear, especially in high-load or high-speed applications. Replace the coupling if it shows significant signs of wear, deformation, or damage that could affect its performance.

- Balancing: In some cases, dynamic balancing of the coupling may be necessary to avoid vibration issues, which could lead to equipment failure or reduced efficiency.

By conducting regular maintenance, you can detect potential issues early and prevent costly breakdowns or production downtimes. It is essential to follow the manufacturer’s guidelines and recommendations for maintenance to ensure optimal performance and longevity of the motor couplings.

“`

Are Grid Couplings Suitable for High Torque and Misalignment Conditions?

Yes, grid couplings are well-suited for high torque and misalignment conditions in industrial applications. They offer several features that make them an excellent choice for such conditions:

- High Torque Capacity: Grid couplings are designed to handle high torque loads, making them suitable for heavy-duty industrial machinery and equipment.

- Misalignment Tolerance: Grid couplings can accommodate both angular and radial misalignments between the connected shafts. This ability to tolerate misalignments is crucial in industrial settings where perfect alignment may not always be possible.

- Vibration Damping: The serrated grid element in grid couplings acts as a vibration damper, absorbing shocks and vibrations that can occur during high-torque operation. This feature helps in reducing noise levels and ensuring smoother machinery performance.

- Shock Load Absorption: Grid couplings are specifically designed to absorb shock loads, which are common in industrial environments. This capability protects the connected equipment from sudden overloads and prevents damage to the machinery.

- Torsional Flexibility: The flexible grid structure of the coupling provides torsional flexibility, allowing it to compensate for torsional vibrations and torque spikes that often occur in high-torque conditions.

Grid couplings are commonly used in applications where high torque is required, such as in pumps, compressors, mixers, and other heavy machinery. Additionally, their ability to handle misalignments makes them suitable for various industrial settings where precise alignment may be challenging.

When properly installed and maintained, grid couplings provide reliable performance in high-torque and misalignment conditions, contributing to smoother machinery operation and extended equipment life.

editor by CX 2024-04-19