Product Description

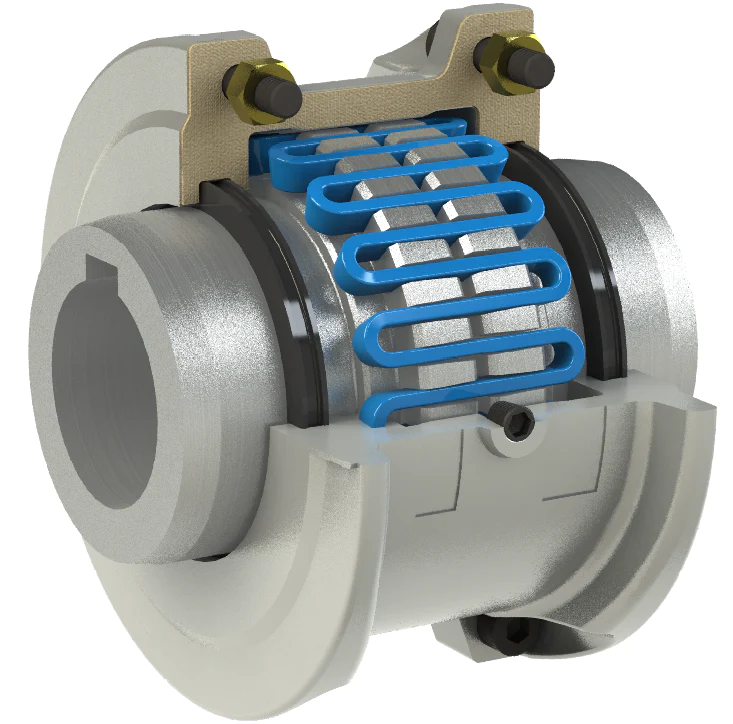

MW Chinese Supplier High Quality Js Type Serpentine Spring Shaft Snake Grid Flexible Coupling Grid Shaft Steel Coupling

1)Flexible jaw coupling: Compact designing, easy installation, convenient maintenance

2)Material: Cast iron, stainless steel, aluminium

Flexible coupling, FCL flexible coupling, mh flexible coupling, flexible shaft coupling, flexible rubber coupling, flexible flange coupling, flexible disc coupling, flexible spring coupling, flexible drive coupling, flexible mechanical coupling, exhaust flexible coupling, flexible spacer coupling, flexible pin coupling, membrane flexible coupling, flexible beam coupling, lovejoy flexible coupling, hrc type flexible coupling, flexible pump rubber coupling, di flexible coupling, flexible coupling spring coupling encoder coupling

Flexible coupling: Compact designing, easy installation, convenient maintenance, small size and light weight.

CNC machined

FCL flexible coupling:

1). Compact designing, easy installation

2). Convenient maintenance, small size and light weight

3). Widely used in medium and minor power transmission system driven by motor such as speed reducers, hoist, compressor, conveyer, spinning and weaving machine and ball mill.

Permittable relative displacement:

1). Radial displacement: 0.2-0.6mm

2). Angle displacement: 0° 30-1° 30

HRC Coupling are designed for general-purpose application where the demand for a

Low cost, spacer type flexible coupling is required. HRC Coupling absorb shock load,

Dampen small amplitude vibration and allow for incidental misalignment. HRC Coupling

Have integrally cast driving dog to maintain a positive drive in the unlikely event of the flexible

Element being destroyed.

With the addition of taper bush HRC Coupling permit quick and easy assembly.

HRC Coupling require no lubrication and are virtually maintenance free making them

Suitable for most environment. HRC Coupling are offered in pilot bore, taper bush with

Both face/hub mount and finished bore with keyway.

There are other item such as aluminum flexible coupling, stainless steel flexible coupling available

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

How to Select the Right Motor Coupling for Specific Torque and Speed Requirements

Selecting the right motor coupling for specific torque and speed requirements is crucial to ensure efficient power transmission and avoid premature failure. Here are the steps to help you make an informed coupling selection:

- Identify Torque and Speed Requirements: Determine the maximum torque and speed (RPM) demands of the driven equipment. Torque is typically given in pound-feet (lb-ft) or Newton-meters (Nm), while speed is measured in revolutions per minute (RPM).

- Consider Service Factor: Factor in the service conditions and potential overload situations to calculate the required torque capacity of the coupling. The service factor is a safety margin applied to the calculated torque to ensure the coupling can handle occasional peak loads or unexpected shock loads.

- Define Misalignment: Assess the potential misalignments that may occur between the motor and driven shafts. Determine the angular, parallel, and axial misalignment expected during operation.

- Choose Coupling Type: Based on the torque and speed requirements, as well as misalignment considerations, choose the appropriate coupling type. Different coupling types, such as elastomeric, grid, gear, or disc couplings, offer various torque capacities and misalignment capabilities.

- Material Selection: Consider the environmental conditions and the properties of the materials used in the coupling. Factors like temperature, chemical exposure, and corrosion resistance should be taken into account when choosing coupling materials.

- Check Size and Dimensions: Ensure that the selected coupling’s size and dimensions are compatible with the motor and driven equipment’s shaft sizes and connection requirements.

- Consult Manufacturer’s Catalog: Refer to the manufacturer’s catalog or coupling datasheets for detailed technical information, torque-speed curves, and misalignment data to match your specific application requirements.

- Factor in Cost and Longevity: Evaluate the cost-effectiveness and expected service life of the coupling. A higher initial investment in a high-quality coupling may result in longer service life and reduced maintenance costs in the long run.

- Seek Expert Advice: If you are unsure about the best coupling for your application, consult with coupling manufacturers or industry experts who can provide recommendations based on your specific requirements.

By following these steps and carefully evaluating your torque and speed requirements, as well as misalignment considerations, you can select the right motor coupling that ensures reliable and efficient power transmission in your mechanical system.

Do motor couplings require regular maintenance, and if so, what does it involve?

Motor couplings do require regular maintenance to ensure their proper functioning and to extend their lifespan. The maintenance procedures typically involve the following steps:

- Inspection: Regular visual inspections are necessary to check for signs of wear, damage, or misalignment. Inspect the coupling for any cracks, corrosion, or unusual vibrations.

- Lubrication: Some motor couplings, especially flexible and universal couplings, require proper lubrication to reduce friction and prevent premature failure. Follow the manufacturer’s recommendations for the type and frequency of lubrication.

- Tightening: Check and tighten the coupling’s fasteners regularly to prevent any loosening that might occur due to continuous operation or vibrations.

- Alignment: Ensuring proper alignment between the motor and driven load is essential for motor couplings. Misalignment can lead to increased stress and wear on the coupling, causing it to fail prematurely.

- Replacement: Over time, motor couplings may experience wear and tear, especially in high-load or high-speed applications. Replace the coupling if it shows significant signs of wear, deformation, or damage that could affect its performance.

- Balancing: In some cases, dynamic balancing of the coupling may be necessary to avoid vibration issues, which could lead to equipment failure or reduced efficiency.

By conducting regular maintenance, you can detect potential issues early and prevent costly breakdowns or production downtimes. It is essential to follow the manufacturer’s guidelines and recommendations for maintenance to ensure optimal performance and longevity of the motor couplings.

“`

Are Grid Couplings Suitable for High Torque and Misalignment Conditions?

Yes, grid couplings are well-suited for high torque and misalignment conditions in industrial applications. They offer several features that make them an excellent choice for such conditions:

- High Torque Capacity: Grid couplings are designed to handle high torque loads, making them suitable for heavy-duty industrial machinery and equipment.

- Misalignment Tolerance: Grid couplings can accommodate both angular and radial misalignments between the connected shafts. This ability to tolerate misalignments is crucial in industrial settings where perfect alignment may not always be possible.

- Vibration Damping: The serrated grid element in grid couplings acts as a vibration damper, absorbing shocks and vibrations that can occur during high-torque operation. This feature helps in reducing noise levels and ensuring smoother machinery performance.

- Shock Load Absorption: Grid couplings are specifically designed to absorb shock loads, which are common in industrial environments. This capability protects the connected equipment from sudden overloads and prevents damage to the machinery.

- Torsional Flexibility: The flexible grid structure of the coupling provides torsional flexibility, allowing it to compensate for torsional vibrations and torque spikes that often occur in high-torque conditions.

Grid couplings are commonly used in applications where high torque is required, such as in pumps, compressors, mixers, and other heavy machinery. Additionally, their ability to handle misalignments makes them suitable for various industrial settings where precise alignment may be challenging.

When properly installed and maintained, grid couplings provide reliable performance in high-torque and misalignment conditions, contributing to smoother machinery operation and extended equipment life.

editor by CX 2024-04-12