Product Description

Flexible flex Fluid Chain Jaw flange Gear Rigid Spacer PIN HRC MH NM universal Fenaflex Oldham spline clamp tyre grid hydraulic servo motor shaft Coupling

Product Description

The function of Shaft coupling:

1. Shafts for connecting separately manufactured units such as motors and generators.

2. If any axis is misaligned.

3. Provides mechanical flexibility.

4. Absorb the transmission of impact load.

5. Prevent overload

We can provide the following couplings.

| Rigid coupling | Flange coupling | Oldham coupling |

| Sleeve or muff coupling | Gear coupling | Bellow coupling |

| Split muff coupling | Flexible coupling | Fluid coupling |

| Clamp or split-muff or compression coupling | Universal coupling | Variable speed coupling |

| Bushed pin-type coupling | Diaphragm coupling | Constant speed coupling |

Company Profile

We are an industrial company specializing in the production of couplings. It has 3 branches: steel casting, forging, and heat treatment. Main products: cross shaft universal coupling, drum gear coupling, non-metallic elastic element coupling, rigid coupling, etc.

The company mainly produces the industry standard JB3241-91 swap JB5513-91 swc. JB3242-93 swz series universal coupling with spider type. It can also design and produce various non-standard universal couplings, other couplings, and mechanical products for users according to special requirements. Currently, the products are mainly sold to major steel companies at home and abroad, the metallurgical steel rolling industry, and leading engine manufacturers, with an annual production capacity of more than 7000 sets.

The company’s quality policy is “quality for survival, variety for development.” In August 2000, the national quality system certification authority audited that its quality assurance system met the requirements of GB/T19002-1994 IDT ISO9002:1994 and obtained the quality system certification certificate with the registration number 0900B5711. It is the first enterprise in the coupling production industry in HangZhou City that passed the ISO9002 quality and constitution certification.

The company pursues the business purpose of “reliable quality, the supremacy of reputation, commitment to business and customer satisfaction” and welcomes customers at home and abroad to choose our products.

At the same time, the company has established long-term cooperative relations with many enterprises and warmly welcomes friends from all walks of life to visit, investigate and negotiate business!

How to use the coupling safely

The coupling is an intermediate connecting part of each motion mechanism, which directly impacts the regular operation of each motion mechanism. Therefore, attention must be paid to:

1. The coupling is not allowed to have more than the specified axis deflection and radial displacement so as not to affect its transmission performance.

2. The bolts of the LINS coupling shall not be loose or damaged.

3. Gear coupling and cross slide coupling shall be lubricated regularly, and lubricating grease shall be added every 2-3 months to avoid severe wear of gear teeth and serious consequences.

4. The tooth width contact length of gear coupling shall not be less than 70%; Its axial displacement shall not be more significant than 5mm

5. The coupling is not allowed to have cracks. If there are cracks, it needs to be replaced (they can be knocked with a small hammer and judged according to the sound).

6. The keys of LINS coupling shall be closely matched and shall not be loosened.

7. The tooth thickness of the gear coupling is worn. When the lifting mechanism exceeds 15% of the original tooth thickness, the operating mechanism exceeds 25%, and the broken tooth is also scrapped.

8. If the elastic ring of the pin coupling and the sealing ring of the gear coupling is damaged or aged, they should be replaced in time.

Certifications

Packaging & Shipping

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Is it Possible to Replace a Motor Coupling Without Professional Assistance?

Replacing a motor coupling can be a relatively straightforward task, and it is possible to do it without professional assistance, depending on your level of mechanical skill and experience. However, it is essential to exercise caution and follow proper procedures to ensure a successful replacement and prevent any potential damage.

If you have a basic understanding of mechanical systems and tools, you can attempt to replace a motor coupling by following these general steps:

- Turn Off Power: Before starting any work, make sure to turn off the power supply to the motor to prevent accidents.

- Access the Coupling: Locate the motor coupling, which connects the motor shaft to the driven shaft or load. It is often situated near the motor or at the input of the driven equipment.

- Remove Guards and Covers: If applicable, remove any guards or covers that may be concealing the coupling and motor assembly.

- Loosen Fasteners: Loosen and remove the fasteners, such as set screws or bolts, that secure the coupling halves to the motor and driven shafts.

- Remove Old Coupling: Carefully slide or separate the old coupling from the motor and driven shafts.

- Install New Coupling: Place the new coupling onto the motor and driven shafts, ensuring proper alignment and engagement.

- Tighten Fasteners: Securely tighten the fasteners to hold the new coupling in place.

- Check Alignment: Verify that the motor and driven shafts are aligned properly to prevent premature wear and damage to the new coupling.

- Replace Guards and Covers: Once the new coupling is installed and aligned, replace any guards or covers that were removed.

- Turn On Power: After completing the replacement, turn the power supply back on and test the motor and driven equipment for proper operation.

While the process seems straightforward, it is essential to refer to the specific instructions provided by the manufacturer of the motor and coupling. Some couplings may have unique installation requirements, and following the manufacturer’s guidelines ensures optimal performance and safety.

If you are unsure about any aspect of the replacement process or encounter difficulties during the procedure, it is recommended to seek assistance from a qualified professional or a trained technician to avoid any potential damage to the motor or equipment.

“`

Real-world examples of motor coupling applications in various industrial setups.

Motor couplings find extensive applications across diverse industrial setups, connecting motors to driven equipment and transmitting torque efficiently. Here are some real-world examples of motor coupling applications:

1. Conveyor Systems

In manufacturing and logistics industries, motor couplings are used in conveyor systems to transfer goods and materials from one point to another. Flexible couplings accommodate misalignments between conveyor sections, while backlash in certain couplings helps absorb shocks from the load and avoid damage.

2. Pumps and Compressors

In water treatment plants, chemical processing facilities, and oil refineries, motor couplings are employed in pumps and compressors. Rigid couplings are often used in high-torque applications where precise alignment is critical to maintain pump efficiency and prevent shaft misalignment issues.

3. CNC Machines

In computer numerical control (CNC) machines, motor couplings connect the spindle motor to the cutting tool or workpiece. High precision and low backlash couplings are used to ensure accurate and repeatable movements during machining operations.

4. Printing Presses

In the printing industry, motor couplings are utilized in printing presses to drive paper feeders, ink rollers, and other components. Flexible couplings help absorb vibrations and misalignments, reducing wear on machine parts and improving print quality.

5. Packaging Machinery

Motor couplings are integral to packaging machinery, such as form-fill-seal machines, capping machines, and labeling systems. Couplings facilitate smooth and reliable motion transmission, allowing for precise and efficient packaging processes.

6. Textile Machinery

In textile manufacturing, motor couplings are used in spinning, weaving, and dyeing machines. Couplings accommodate frequent starts and stops, shock loads, and speed variations, ensuring stable and consistent operation.

7. Robotics

In industrial robotics, motor couplings are vital components that connect the motor to the robotic arms and joints. High-performance couplings with low backlash and high torsional stiffness are used to achieve precise and responsive robot movements.

8. Food Processing Equipment

Motor couplings are found in food processing equipment, including mixers, grinders, and slicers. Stainless steel couplings are often used to meet hygiene standards, while flexible couplings protect motors and gearboxes from sudden loads during food processing.

These examples highlight the versatility of motor couplings in various industrial applications. The choice of coupling type depends on factors such as load characteristics, speed requirements, misalignment allowances, and specific environmental conditions in each industrial setup.

“`

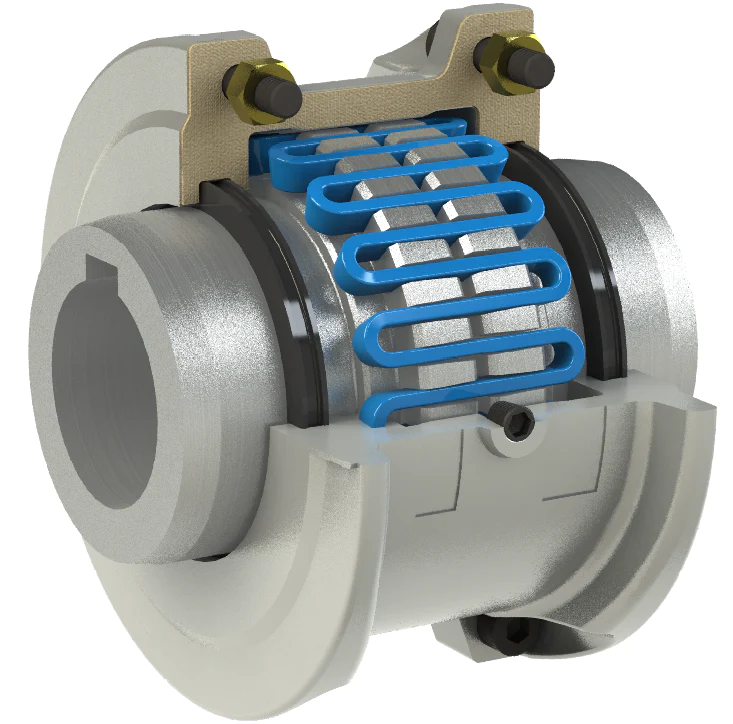

How to Properly Install a Grid Coupling for Reliable Performance

Proper installation of a grid coupling is crucial for ensuring reliable performance and maximizing its lifespan. Here are the steps to install a grid coupling correctly:

- Preparation: Before installation, ensure that the shafts and coupling hubs are clean and free from any debris or contaminants. Inspect the grid coupling and its components for any signs of damage or wear.

- Align the Shafts: Make sure that the shafts to be connected are properly aligned. Grid couplings can accommodate some degree of misalignment, but it is essential to minimize it for optimal performance.

- Assemble the Grid: Insert the serrated grid element between the two coupling hubs. Ensure that the grid is centered and aligned with the hubs’ teeth.

- Tighten the Fasteners: Use the appropriate torque wrench to tighten the fasteners that secure the coupling hubs together. Follow the manufacturer’s recommended torque values to avoid over-tightening or under-tightening.

- Check Runout: After installation, check the coupling’s runout by rotating the connected shafts. Excessive runout indicates a potential misalignment or installation issue.

- Lubrication: Some grid couplings require lubrication for optimal performance. Refer to the manufacturer’s guidelines and apply the recommended lubricant to the coupling components.

- Check for Smooth Operation: Start the machinery and observe the coupling’s operation. Listen for any unusual noises or vibrations that may indicate a problem. If any issues are detected, stop the machinery and inspect the coupling again.

- Regular Maintenance: Schedule regular maintenance checks to ensure the coupling’s ongoing reliability. Inspect for signs of wear, misalignment, or damage, and replace any worn or damaged components as needed.

It is essential to follow the manufacturer’s installation guidelines and recommendations specific to the grid coupling model being used. Proper installation and regular maintenance will ensure the grid coupling performs reliably and efficiently, providing effective power transmission in industrial machinery and equipment.

editor by CX 2024-02-19