Product Description

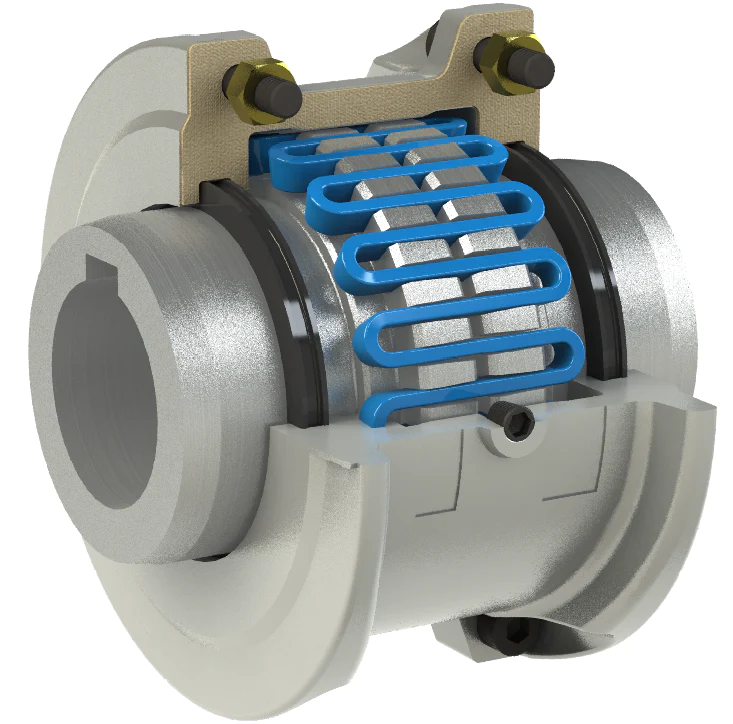

JS600 Series Grid Coupling

Grid Coupling is widely used in metallurgy, mining, lifting, transportation, petroleum, chemical, ships, textile, light industry, agricultural machinery, printing machines and pumps, fans, compressors, machine tools and other mechanical equipment and industry shaft transmission.

♦Feature

1.The serpentine spring as the elastic element, the elastic strong at the same time, greatly improves the grid coupling torque, widely used in heavy machinery and general machinery.The serpentine spring special technology department, has long service life, allowing higher speed, has good ability to compensate in the axial, radial and angle

2.High transmission efficiency, start safety. Transmission efficiency of up to 99.47%, short-time overload capacity is 2 times the rated torque, operation safety.

3.Simple structure, convenient assembly and disassembly, long service life

4.Damping effect is good to avoid the resonance.

♦Basic Parameter And Main Dimension

| Brake wheel Diameter× thickness E×F |

Model | Nominal Torque Nm |

Speed r/min |

Y,Z Bore d1,d2 |

D | L | A | G | P | M | N | W | Clearance (K) | No bore mass Kg |

||||

| Max | Min | One-way brake wheel | Two- way brake wheel |

Min | Standard | Max | ||||||||||||

| 120×60 | JS601 | 10 | 4500 | 28 | 14 | 98 | 52 | 40 | 35 | 95 | 35 | 65 | 62 | 92 | 1.5 | 3 | 5 | 0.03 |

| 125×70 | JS602 | 35 | 4500 | 35 | 14 | 110 | 52 | 50 | 35 | 105 | 35 | 70 | 62 | 92 | 1.5 | 3 | 5 | 0.03 |

| 140×82 | JS603 | 65 | 4170 | 42 | 14 | 120 | 52 | 55 | 35 | 117 | 35 | 76 | 62 | 92 | 1.5 | 3 | 5 | 0.06 |

| 180×108 | JS604 | 117 | 3270 | 48 | 14 | 138 | 62 | 65 | 40 | 148 | 40 | 94 | 62 | 92 | 1.5 | 3 | 5 | 0.06 |

| 205×90 | JS605 | 207 | 2870 | 55 | 19 | 155 | 62 | 75 | 45 | 135 | 46 | 90 | 87 | 117 | 1.5 | 3 | 5 | 0.09 |

| 255×95 | JS606 | 328 | 2300 | 65 | 19 | 170 | 82 | 90 | 47 | 142 | 48 | 94.5 | 87 | 117 | 1.5 | 3 | 5 | 0.09 |

| 280×128 | JS607 | 630 | 2080 | 75 | 28 | 195 | 112 | 105 | 60 | 188 | 58 | 124 | 87 | 152 | 1.5 | 4 | 6.5 | 0.17 |

| 330×145 | JS608 | 1000 | 1770 | 85 | 28 | 212 | 112 | 125 | 14 | 159 | 109 | 86.5 | 87 | 152 | 1.5 | 4 | 6.5 | 0.26 |

| 405×170 | JS609 | 1800 | 1430 | 100 | 42 | 248 | 142 | 140 | 16 | 186 | 138 | 101 | 122 | 152 | 1.5 | 6 | 10 | 0.43 |

| 485×220 | JS610 | 2800 | 1200 | 110 | 42 | 274 | 142 | 160 | -7 | 213 | 168 | 103 | 147 | 167 | 1.5 | 6 | 10 | 0.51 |

| 535×250 | JS611 | 4300 | 1100 | 125 | 60 | 324 | 142 | 180 | -7 | 243 | 200 | 118 | 147 | 167 | 1.5 | 6 | 13 | 0.74 |

| 585×285 | JS612 | 6000 | 1000 | 150 | 70 | 368 | 172 | 220 | -25 | 260 | 250 | 84.5 | 152 | 182 | 1.5 | 6 | 13 | 0.91 |

| 670×305 | JS613 | 8700 | 850 | 180 | 70 | 400 | 172 | 255 | 0 | 300 | 275 | 150 | 152 | 182 | 1.5 | 6 | 13 | 1.14 |

| 760×305 | JS614 | 12000 | 765 | 200 | 110 | 458 | 212 | 270 | 0 | 305 | 275 | 152.5 | 182 | 182 | 3 | 6 | 13 | 1.9 |

| 765×310 | JS615 | 16000 | 765 | 220 | 120 | 500 | 212 | 305 | 0 | 310 | 275 | 155 | 197 | 197 | 3 | 6 | 13 | 2.8 |

♦Product Show

♦Other Products List

| Transmission Machinery Parts Name |

Model |

| Universal Coupling | WS,WSD,WSP |

| Cardan Shaft | SWC,SWP,SWZ |

| Tooth Coupling | CL,CLZ,GCLD,GIICL, GICL,NGCL,GGCL,GCLK |

| Disc Coupling | JMI,JMIJ,JMII,JMIIJ |

| High Flexible Coupling | LM |

| Chain Coupling | GL |

| Jaw Coupling | LT |

| Grid Coupling | JS |

♦Our Company

HangZhou CHINAMFG Machinery Manufacturing Co., Ltd. is a high-tech enterprise specializing in the design and manufacture of various types of coupling. There are 86 employees in our company, including 2 senior engineers and no fewer than 20 mechanical design and manufacture, heat treatment, welding, and other professionals.

Advanced and reasonable process, complete detection means. Our company actively introduces foreign advanced technology and equipment, on the basis of the condition, we make full use of the advantage and do more research and innovation. Strict to high quality and operate strictly in accordance with the ISO9000 quality certification system standard mode.

Our company supplies different kinds of products. High quality and reasonable price. We stick to the principle of “quality first, service first, continuous improvement and innovation to meet the customers” for the management and “zero defect, zero complaints” as the quality objective.

♦Our Services

1.Design Services

Our design team has experience in cardan shaft relating to product design and development. If you have any needs for your new product or wish to make further improvements, we are here to offer our support.

2.Product Services

raw materials → Cutting → Forging →Rough machining →Shot blasting →Heat treatment →Testing →Fashioning →Cleaning→ Assembly→Packing→Shipping

3.Samples Procedure

We could develop the sample according to your requirement and amend the sample constantly to meet your need.

4.Research & Development

We usually research the new needs of the market and develop the new model when there is new cars in the market.

5.Quality Control

Every step should be special test by Professional Staff according to the standard of ISO9001 and TS16949.

♦FAQ

Q 1: Are you trading company or manufacturer?

A: We are a professional manufacturer specializing in manufacturing

various series of couplings.

Q 2:Can you do OEM?

Yes, we can. We can do OEM & ODM for all the customers with customized artworks of PDF or AI format.

Q 3:How long is your delivery time?

Generally it is 20-30 days if the goods are not in stock. It is according to quantity.

Q 4: Do you provide samples ? Is it free or extra ?

Yes, we could offer the sample but not for free.Actually we have a very good price principle, when you make the bulk order then cost of sample will be deducted.

Q 5: How long is your warranty?

A: Our Warranty is 12 month under normal circumstance.

Q 6: What is the MOQ?

A:Usually our MOQ is 1pcs.

Q 7: Do you have inspection procedures for coupling ?

A:100% self-inspection before packing.

Q 8: Can I have a visit to your factory before the order?

A: Sure,welcome to visit our factory.

Q 9: What’s your payment?

A:1) T/T.

♦Contact Us

Web: huadingcoupling

Add: No.11 HangZhou Road,Chengnan park,HangZhou City,ZheJiang Province,China /* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Is it Possible to Replace a Motor Coupling Without Professional Assistance?

Replacing a motor coupling can be a relatively straightforward task, and it is possible to do it without professional assistance, depending on your level of mechanical skill and experience. However, it is essential to exercise caution and follow proper procedures to ensure a successful replacement and prevent any potential damage.

If you have a basic understanding of mechanical systems and tools, you can attempt to replace a motor coupling by following these general steps:

- Turn Off Power: Before starting any work, make sure to turn off the power supply to the motor to prevent accidents.

- Access the Coupling: Locate the motor coupling, which connects the motor shaft to the driven shaft or load. It is often situated near the motor or at the input of the driven equipment.

- Remove Guards and Covers: If applicable, remove any guards or covers that may be concealing the coupling and motor assembly.

- Loosen Fasteners: Loosen and remove the fasteners, such as set screws or bolts, that secure the coupling halves to the motor and driven shafts.

- Remove Old Coupling: Carefully slide or separate the old coupling from the motor and driven shafts.

- Install New Coupling: Place the new coupling onto the motor and driven shafts, ensuring proper alignment and engagement.

- Tighten Fasteners: Securely tighten the fasteners to hold the new coupling in place.

- Check Alignment: Verify that the motor and driven shafts are aligned properly to prevent premature wear and damage to the new coupling.

- Replace Guards and Covers: Once the new coupling is installed and aligned, replace any guards or covers that were removed.

- Turn On Power: After completing the replacement, turn the power supply back on and test the motor and driven equipment for proper operation.

While the process seems straightforward, it is essential to refer to the specific instructions provided by the manufacturer of the motor and coupling. Some couplings may have unique installation requirements, and following the manufacturer’s guidelines ensures optimal performance and safety.

If you are unsure about any aspect of the replacement process or encounter difficulties during the procedure, it is recommended to seek assistance from a qualified professional or a trained technician to avoid any potential damage to the motor or equipment.

“`

Can motor couplings handle reversing loads and shock loads effectively?

Motor couplings are designed to handle various types of loads, including reversing loads and shock loads, effectively. Let’s explore their capabilities in dealing with these load conditions:

1. Reversing Loads

Reversing loads occur when the direction of the transmitted torque alternates periodically. Motor couplings, especially flexible couplings and universal couplings (Hooke’s joints), are well-suited for handling reversing loads. These couplings can accommodate angular misalignments between the motor and driven load, allowing for smooth torque transmission even during direction changes. Properly aligned and maintained couplings can endure frequent reversals without significant wear or fatigue.

2. Shock Loads

Shock loads refer to sudden and intense forces that exceed the typical operating conditions. These loads can occur due to abrupt starts, stops, or impacts in the system. Motor couplings, particularly those with some level of flexibility, possess inherent shock-absorbing properties. Flexible couplings can dampen the impact of sudden loads, reducing the stress on connected components and preventing damage. Rigid couplings are less forgiving to shock loads but may still be suitable for certain applications where the impact is within their load-bearing capacity.

However, it’s essential to consider the specific application requirements and choose the appropriate coupling type based on the expected load conditions. Factors such as the magnitude and frequency of reversing and shock loads, system dynamics, and the overall design should be considered when selecting a motor coupling. Additionally, regular maintenance and inspection play a crucial role in ensuring that the couplings continue to perform effectively under challenging load conditions.

“`

Advantages of Using Grid Couplings in Industrial Machinery and Equipment

Grid couplings offer several advantages in industrial machinery and equipment applications, making them a popular choice for power transmission systems. Some of the key advantages include:

- High Torque Capacity: Grid couplings have a high torque capacity, allowing them to transmit significant amounts of torque between shafts. This makes them suitable for heavy-duty industrial applications that require substantial power transmission.

- Misalignment Tolerance: One of the primary benefits of grid couplings is their ability to accommodate misalignments between the connected shafts. They can handle both angular and radial misalignments, reducing stress on the machinery and extending component life.

- Vibration Damping: The serrated grid element in grid couplings acts as a vibration damper, absorbing shocks and vibrations that can occur during operation. This feature helps in reducing noise levels and ensuring smoother machinery performance.

- Shock Load Absorption: Grid couplings are designed to absorb shock loads, which are common in industrial environments. This capability protects the connected equipment from sudden overloads and prevents damage to the machinery.

- Torsional Flexibility: The flexible grid structure of the coupling provides torsional flexibility, allowing it to compensate for torsional vibrations and torque spikes. This feature contributes to improved system stability and reduced stress on components.

- Easy Installation and Maintenance: Grid couplings are relatively easy to install, making them a convenient choice for machinery assembly. They also require minimal maintenance, resulting in cost savings and reduced downtime for equipment servicing.

- Wide Range of Applications: Grid couplings are versatile and suitable for various industries, including mining, pulp and paper, steel mills, and power generation. They are employed in pumps, compressors, fans, conveyors, mixers, and other industrial equipment.

- Cost-Effective: Considering their durability, misalignment tolerance, and low maintenance requirements, grid couplings offer a cost-effective solution for power transmission needs in industrial settings.

Overall, grid couplings provide a robust and reliable means of transmitting power between rotating shafts while protecting machinery from adverse conditions. Their ability to handle misalignments and dampen vibrations makes them a valuable component in a wide range of industrial applications.

editor by CX 2024-03-05