Product Description

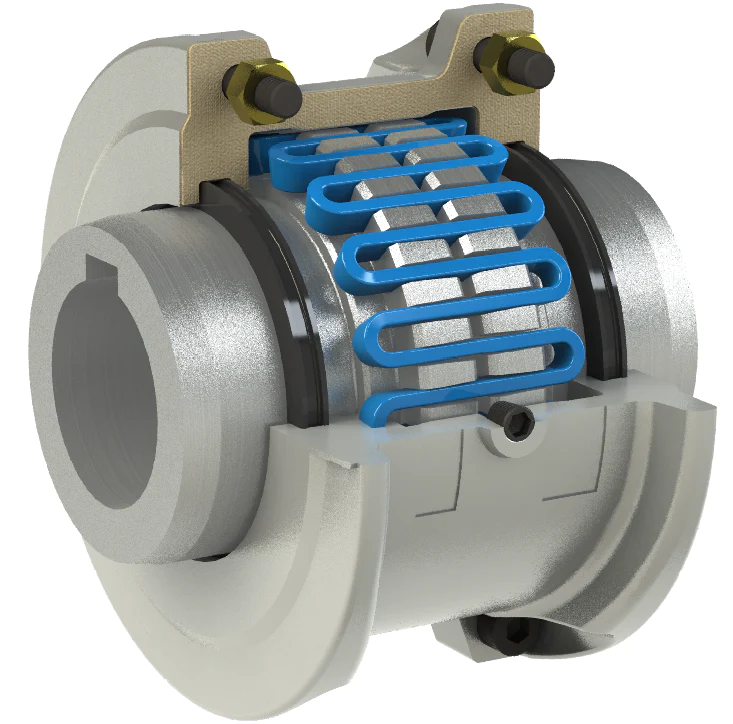

High Quality Snake Spring Grid Coupling Flexible Shaft Coupling

Description:

JS grid coupling vibration, JS grid coupling and long service life. JS grid coupling under high load range, JS grid coupling

starting safety, high transmission efficiency, reliable operation.

Features:

1.The serpentine spring as the elastic element, the elastic strong at the same time, greatly improves the grid coupling torque, widely used in heavy machinery and general machinery.The serpentine spring special technology department, has long service life, allowing higher speed, has good ability to compensate in the axial, radial and angle

2.High transmission efficiency, start safety. Transmission efficiency of up to 99.47%, short-time overload capacity is 2 times the rated torque, operation safety.

3.Simple structure, convenient assembly and disassembly, long service life

4.Damping effect is good to avoid the resonance.

Product parameters:

Packing & shipping:

1 Prevent from damage.

2. As customers’ requirements, in perfect condition.

3. Delivery : As per contract delivery on time

4. Shipping : As per client request. We can accept CIF, Door to Door etc. or client authorized agent we supply all the necessary assistant.

FAQ:

Q 1: Are you a trading company or a manufacturer?

A: We are a professional manufacturer specializing in manufacturing various series of couplings.

Q 2:Can you do OEM?

Yes, we can. We can do OEM & ODM for all the customers with customized artworks in PDF or AI format.

Q 3:How long is your delivery time?

Generally, it is 20-30 days if the goods are not in stock. It is according to quantity.

Q 4: How long is your warranty?

A: Our Warranty is 12 months under normal circumstances.

Q 5: Do you have inspection procedures for coupling?

A:100% self-inspection before packing.

Q 6: Can I have a visit to your factory before the order?

A: Sure, welcome to visit our factory.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Is it Possible to Replace a Motor Coupling Without Professional Assistance?

Replacing a motor coupling can be a relatively straightforward task, and it is possible to do it without professional assistance, depending on your level of mechanical skill and experience. However, it is essential to exercise caution and follow proper procedures to ensure a successful replacement and prevent any potential damage.

If you have a basic understanding of mechanical systems and tools, you can attempt to replace a motor coupling by following these general steps:

- Turn Off Power: Before starting any work, make sure to turn off the power supply to the motor to prevent accidents.

- Access the Coupling: Locate the motor coupling, which connects the motor shaft to the driven shaft or load. It is often situated near the motor or at the input of the driven equipment.

- Remove Guards and Covers: If applicable, remove any guards or covers that may be concealing the coupling and motor assembly.

- Loosen Fasteners: Loosen and remove the fasteners, such as set screws or bolts, that secure the coupling halves to the motor and driven shafts.

- Remove Old Coupling: Carefully slide or separate the old coupling from the motor and driven shafts.

- Install New Coupling: Place the new coupling onto the motor and driven shafts, ensuring proper alignment and engagement.

- Tighten Fasteners: Securely tighten the fasteners to hold the new coupling in place.

- Check Alignment: Verify that the motor and driven shafts are aligned properly to prevent premature wear and damage to the new coupling.

- Replace Guards and Covers: Once the new coupling is installed and aligned, replace any guards or covers that were removed.

- Turn On Power: After completing the replacement, turn the power supply back on and test the motor and driven equipment for proper operation.

While the process seems straightforward, it is essential to refer to the specific instructions provided by the manufacturer of the motor and coupling. Some couplings may have unique installation requirements, and following the manufacturer’s guidelines ensures optimal performance and safety.

If you are unsure about any aspect of the replacement process or encounter difficulties during the procedure, it is recommended to seek assistance from a qualified professional or a trained technician to avoid any potential damage to the motor or equipment.

“`

Can motor couplings handle reversing loads and shock loads effectively?

Motor couplings are designed to handle various types of loads, including reversing loads and shock loads, effectively. Let’s explore their capabilities in dealing with these load conditions:

1. Reversing Loads

Reversing loads occur when the direction of the transmitted torque alternates periodically. Motor couplings, especially flexible couplings and universal couplings (Hooke’s joints), are well-suited for handling reversing loads. These couplings can accommodate angular misalignments between the motor and driven load, allowing for smooth torque transmission even during direction changes. Properly aligned and maintained couplings can endure frequent reversals without significant wear or fatigue.

2. Shock Loads

Shock loads refer to sudden and intense forces that exceed the typical operating conditions. These loads can occur due to abrupt starts, stops, or impacts in the system. Motor couplings, particularly those with some level of flexibility, possess inherent shock-absorbing properties. Flexible couplings can dampen the impact of sudden loads, reducing the stress on connected components and preventing damage. Rigid couplings are less forgiving to shock loads but may still be suitable for certain applications where the impact is within their load-bearing capacity.

However, it’s essential to consider the specific application requirements and choose the appropriate coupling type based on the expected load conditions. Factors such as the magnitude and frequency of reversing and shock loads, system dynamics, and the overall design should be considered when selecting a motor coupling. Additionally, regular maintenance and inspection play a crucial role in ensuring that the couplings continue to perform effectively under challenging load conditions.

“`

How to Properly Install a Grid Coupling for Reliable Performance

Proper installation of a grid coupling is crucial for ensuring reliable performance and maximizing its lifespan. Here are the steps to install a grid coupling correctly:

- Preparation: Before installation, ensure that the shafts and coupling hubs are clean and free from any debris or contaminants. Inspect the grid coupling and its components for any signs of damage or wear.

- Align the Shafts: Make sure that the shafts to be connected are properly aligned. Grid couplings can accommodate some degree of misalignment, but it is essential to minimize it for optimal performance.

- Assemble the Grid: Insert the serrated grid element between the two coupling hubs. Ensure that the grid is centered and aligned with the hubs’ teeth.

- Tighten the Fasteners: Use the appropriate torque wrench to tighten the fasteners that secure the coupling hubs together. Follow the manufacturer’s recommended torque values to avoid over-tightening or under-tightening.

- Check Runout: After installation, check the coupling’s runout by rotating the connected shafts. Excessive runout indicates a potential misalignment or installation issue.

- Lubrication: Some grid couplings require lubrication for optimal performance. Refer to the manufacturer’s guidelines and apply the recommended lubricant to the coupling components.

- Check for Smooth Operation: Start the machinery and observe the coupling’s operation. Listen for any unusual noises or vibrations that may indicate a problem. If any issues are detected, stop the machinery and inspect the coupling again.

- Regular Maintenance: Schedule regular maintenance checks to ensure the coupling’s ongoing reliability. Inspect for signs of wear, misalignment, or damage, and replace any worn or damaged components as needed.

It is essential to follow the manufacturer’s installation guidelines and recommendations specific to the grid coupling model being used. Proper installation and regular maintenance will ensure the grid coupling performs reliably and efficiently, providing effective power transmission in industrial machinery and equipment.

editor by CX 2024-03-11