Product Description

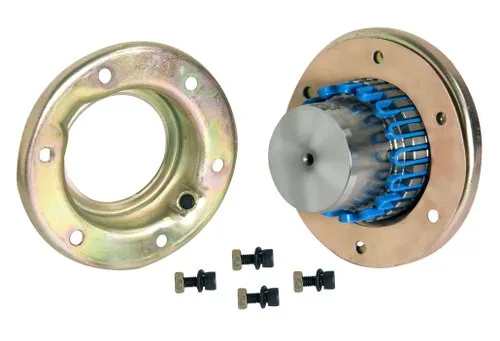

Densen customized grid spring coupling,steel grid coupling,grid flexible coupling

| Product Name | Densen customized grid spring coupling,steel grid coupling,grid flexible coupling |

| DN mm | 11~180mm |

| Axis Angle | 1°00/1°30 |

| Rated Torque | 10~25000 N·m |

| Allowable speed | 5000~350N·m |

| Material | 35CrMo/HT200/ZG270 |

| Application | Widely used in metallurgy, mining, engineering and other fields. |

Products show

Features:

1,Double-diaphragm and small axial opposite wheel type coupling is the patent product developed by our factory,the patent No. ZL.99 2 46247.9

2,With compact strcture, the adjustment capacity,anti-inpact and vibration-absorbing etc properties will be higher by 35%-40% than those of single diaphragm opposite wheel type.

3,Under unexpected diaphragm breakage conditions, the plum CHINAMFG shape flange can still transfer the torque ,the safety property is good .

Company Information

Equipment

Application Case

Typical case of diaphragm coupling applied to variable frequency speed control equipment

JMB type coupling is applied to HangZhou Oilfield Thermal Power Plant

According to the requirements of HangZhou Electric Power Corporation, HangZhou Oilfield Thermal Power Plant should dynamically adjust the power generation according to the load of the power grid and market demand, and carry out the transformation of the frequency converter and the suction fan. The motor was originally a 1600KW, 730RPM non-frequency variable speed motor matched by HangZhou Motor Factory. The speed control mode after changing the frequency is manual control. Press the button speed to increase 10RPM or drop 10RPM. The coupling is still the original elastic decoupling coupling, and the elastic de-coupling coupling after frequency conversion is frequently damaged, which directly affects the normal power generation.

It is found through analysis that in the process of frequency conversion speed regulation, the pin of the coupling can not bear the inertia of the speed regulation process (the diameter of the fan impeller is 3.3 meters) and is cut off, which has great damage to the motor and the fan.

Later, they switched to the JMB460 double-diaphragm wheel-type coupling of our factory (patent number: ZL.99246247.9). After 1 hour of destructive experiment and more than 1 year of operation test, the equipment is running very well, and there is no Replace the diaphragm. 12 units have been rebuilt and the operation is in good condition.

Other Application Case

Spare parts

Packaging & Shipping

Contact us

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Materials Used in Manufacturing Grid Couplings

Grid couplings are designed to withstand high torque and provide flexibility while transmitting power in various industrial applications. The materials used in manufacturing grid couplings are chosen for their mechanical properties and durability. The common materials include:

- Cast Iron: Cast iron is a popular choice for the grid, hub, and outer flange components of the coupling. It offers excellent strength and wear resistance, making it suitable for heavy-duty applications.

- Steel: Steel is often used for the grid element or grid springs. It provides the required flexibility and resilience to handle misalignments and shock loads effectively.

- Alloy Steel: Alloy steel may be used for certain high-performance grid couplings. It offers enhanced strength and toughness, making it suitable for demanding industrial environments.

- Stainless Steel: Stainless steel is employed when corrosion resistance is a primary concern. It is commonly used in couplings for applications in corrosive or hygienic environments.

- Non-Metallic Materials: Some modern grid couplings use non-metallic materials, such as high-strength composites or synthetic polymers, for the grid element. These materials offer excellent dampening properties, reduce noise, and prevent electrical conductivity.

The specific material selection depends on factors like the application requirements, environmental conditions, and the level of load and torque the coupling needs to handle. Manufacturers carefully engineer grid couplings to ensure they meet the performance demands of the intended application while providing reliable and efficient power transmission.

“`

What are the temperature and speed limits for different motor coupling types?

The temperature and speed limits for motor couplings vary depending on their design, materials, and intended applications. Below are general guidelines for different motor coupling types:

1. Flexible Couplings

Flexible couplings usually have temperature limits ranging from -40°C to 120°C (-40°F to 248°F). The speed limits for flexible couplings typically range from a few hundred RPM (Revolutions Per Minute) to several thousand RPM, depending on the size and design.

2. Rigid Couplings

Rigid couplings can handle higher temperatures, often ranging from -20°C to 150°C (-4°F to 302°F). Their speed limits are generally higher and can extend into tens of thousands of RPM.

3. Universal Couplings (Hooke’s Joints)

Universal couplings have temperature limits similar to flexible couplings, ranging from -40°C to 120°C (-40°F to 248°F). The speed limits for universal couplings are usually lower compared to flexible or rigid couplings and are typically in the range of a few hundred to a few thousand RPM.

4. Gear Couplings

Gear couplings are capable of handling higher temperatures, ranging from -10°C to 200°C (14°F to 392°F). The speed limits for gear couplings are also high and can extend into tens of thousands of RPM.

5. Disc Couplings

Disc couplings have a broader range of temperature limits, usually from -50°C to 150°C (-58°F to 302°F). Their speed limits are typically in the range of several thousand RPM.

6. Grid Couplings

Grid couplings typically have temperature limits ranging from -20°C to 120°C (-4°F to 248°F). The speed limits for grid couplings vary but can be in the range of several thousand RPM.

It is essential to consider the specific manufacturer’s specifications and recommendations for each motor coupling type, as they may vary based on construction materials, lubrication, and other factors. Operating the couplings within their specified temperature and speed limits ensures optimal performance and extends their service life.

“`

Advantages of Using Grid Couplings in Industrial Machinery and Equipment

Grid couplings offer several advantages in industrial machinery and equipment applications, making them a popular choice for power transmission systems. Some of the key advantages include:

- High Torque Capacity: Grid couplings have a high torque capacity, allowing them to transmit significant amounts of torque between shafts. This makes them suitable for heavy-duty industrial applications that require substantial power transmission.

- Misalignment Tolerance: One of the primary benefits of grid couplings is their ability to accommodate misalignments between the connected shafts. They can handle both angular and radial misalignments, reducing stress on the machinery and extending component life.

- Vibration Damping: The serrated grid element in grid couplings acts as a vibration damper, absorbing shocks and vibrations that can occur during operation. This feature helps in reducing noise levels and ensuring smoother machinery performance.

- Shock Load Absorption: Grid couplings are designed to absorb shock loads, which are common in industrial environments. This capability protects the connected equipment from sudden overloads and prevents damage to the machinery.

- Torsional Flexibility: The flexible grid structure of the coupling provides torsional flexibility, allowing it to compensate for torsional vibrations and torque spikes. This feature contributes to improved system stability and reduced stress on components.

- Easy Installation and Maintenance: Grid couplings are relatively easy to install, making them a convenient choice for machinery assembly. They also require minimal maintenance, resulting in cost savings and reduced downtime for equipment servicing.

- Wide Range of Applications: Grid couplings are versatile and suitable for various industries, including mining, pulp and paper, steel mills, and power generation. They are employed in pumps, compressors, fans, conveyors, mixers, and other industrial equipment.

- Cost-Effective: Considering their durability, misalignment tolerance, and low maintenance requirements, grid couplings offer a cost-effective solution for power transmission needs in industrial settings.

Overall, grid couplings provide a robust and reliable means of transmitting power between rotating shafts while protecting machinery from adverse conditions. Their ability to handle misalignments and dampen vibrations makes them a valuable component in a wide range of industrial applications.

editor by CX 2024-03-14