Product Description

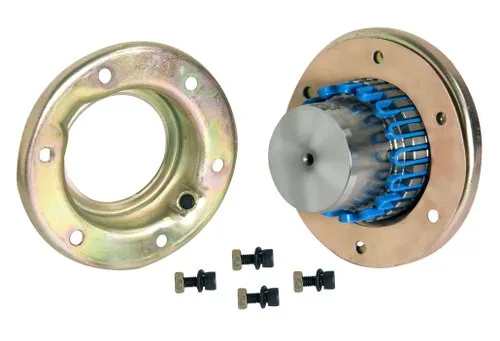

JS500 Series Teletransmission Type Grid Coupling

♦Description

Grid Coupling is widely used in metallurgy, mining, lifting, transportation, petroleum, chemical, ships, textile, light industry, agricultural machinery, printing machines and pumps, fans, compressors, machine tools, and other mechanical equipment and industry shaft transmission.

♦Feature

1. The serpentine spring as the elastic element, the elastic strong at the same time, greatly improve the grid coupling torque, widely used in heavy machinery and general machinery. The serpentine spring special technology department, has a long service life, allowing higher speed, has a good ability to compensate in the axial, radial, and angle

2. High transmission efficiency, start safety. Transmission efficiency of up to 99.47%, short-time overload capacity is 2 times the rated torque, and operation safety.

3. Simple structure, convenient assembly, and disassembly, long service life

4. Damping effect is good to avoid resonance.

♦Basic Parameter and Main Dimension

| Model | Norminal Torque N.m |

Speed r/min |

Y,Z Bore d1,d2 |

A | BE Min |

D | E | N | L | M | P | J | SB | SD | Clearance (K) | No more mass Kg |

|||

| Max | Min | Min | Standard | Max | |||||||||||||||

| JS502 | 125 | 4500 | 35 | 14 | 50 | 160 | 120 | 80 | 80 | 52 | 78 | 27 | 50 | 32 | 38 | 1.5 | 3 | 5 | 4 |

| JS504 | 400 | 4500 | 48 | 14 | 65 | 195 | 160 | 105 | 105 | 62 | 95 | 36 | 60 | 32 | 38 | 1.5 | 3 | 5 | 9 |

| JS506 | 900 | 3900 | 65 | 19 | 90 | 210 | 185 | 125 | 130 | 82 | 105 | 50 | 65 | 45 | 50 | 1.5 | 3 | 5 | 15.5 |

| JS507 | 1800 | 3500 | 75 | 28 | 105 | 275 | 218 | 150 | 156 | 112 | 135 | 52 | 86 | 60 | 65 | 1.5 | 3 | 5 | 26 |

| JS508 | 3150 | 3500 | 85 | 28 | 125 | 295 | 245 | 180 | 175 | 112 | 145 | 58 | 92 | 70 | 75 | 1.5 | 3 | 5 | 37 |

| JS509 | 5600 | 2450 | 100 | 42 | 140 | 370 | 286 | 210 | 208 | 142 | 180 | 70 | 118 | 90 | 95 | 1.5 | 3 | 5 | 63 |

| JS510 | 8000 | 2300 | 110 | 42 | 160 | 390 | 325 | 245 | 230 | 142 | 190 | 74 | 125 | 100 | 105 | 1.5 | 4 | 6.5 | 83 |

| JS511 | 12500 | 2000 | 125 | 60 | 180 | 450 | 330 | 180 | 258 | 142 | 220 | 85 | 150 | 115 | 120 | 1.5 | 4 | 6.5 | 97 |

| JS512 | 18000 | 1800 | 150 | 70 | 220 | 465 | 365 | 220 | 295 | 172 | 225 | 95 | 150 | 130 | 135 | 1.5 | 6 | 10 | 139 |

| JS513 | 25000 | 1600 | 180 | 70 | 255 | 480 | 420 | 255 | 335 | 172 | 235 | 115 | 156 | 140 | 145 | 1.5 | 6 | 10 | 208 |

| JS514 | 35500 | 1500 | 200 | 110 | 270 | 550 | 480 | 270 | 390 | 212 | 270 | 105 | 178 | 160 | 165 | 3 | 6 | 13 | 275 |

| JS515 | 50000 | 1300 | 220 | 120 | 305 | 590 | 550 | 305 | 440 | 212 | 290 | 110 | 190 | 200 | 205 | 3 | 6 | 13 | 378 |

| JS516 | 63000 | 1200 | 250 | 130 | 360 | 620 | 605 | 355 | 495 | 252 | 305 | 125 | 200 | 200 | 205 | 3 | 6 | 13 | 515 |

| JS517 | 90000 | 1100 | 275 | 395 | 675 | 665 | 395 | 550 | 252 | 330 | 140 | 227 | 225 | 230 | 3 | 6 | 13 | 712 | |

| JS518 | 125000 | 1000 | 305 | 440 | 710 | 710 | 430 | 600 | 302 | 350 | 160 | 242 | 250 | 255 | 3 | 6 | 13 | 890 | |

| JS519 | 180000 | 900 | 330 | 500 | 745 | 780 | 495 | 660 | 302 | 365 | 175 | 252 | 275 | 280 | 3 | 6 | 13 | 1196 | |

Note: “Single” refers to the weight of 1 coupling on the left or 1 coupling on the right.

♦Other Products List

| Transmission Machinery Parts Name |

Model |

| Universal Coupling | WS, WSD, WSP |

| Cardan Shaft | SWC,SWP,SWZ |

| Tooth Coupling | CL,CLZ,GCLD,GIICL, GICL,NGCL,GGCL,GCLK |

| Disc Coupling | JMI, JMIJ, JMII, JMIIJ |

| High Flexible Coupling | LM |

| Chain Coupling | GL |

| Jaw Coupling | LT |

| Grid Coupling | JS |

♦Our Company

HangZhou CHINAMFG Machinery Manufacturing Co., Ltd. is a high-tech enterprise specializing in the design and manufacture of various types of coupling. There are 86 employees in our company, including 2 senior engineers and no fewer than 20 mechanical design and manufacture, heat treatment, welding, and other professionals.

Advanced and reasonable process, complete detection means. Our company actively introduces foreign advanced technology and equipment, on the basis of the condition, we make full use of the advantage and do more research and innovation. Strict to high quality and operate strictly in accordance with the ISO9000 quality certification system standard mode.

Our company supplies different kinds of products. High quality and reasonable price. We stick to the principle of “quality first, service first, continuous improvement and innovation to meet the customers” for the management and “zero defect, zero complaints” as the quality objective.

♦Our Services

1.Design Services

Our design team has experience in cardan shaft relating to product design and development. If you have any needs for your new product or wish to make further improvements, we are here to offer our support.

2.Product Services

Raw materials → Cutting → Forging →Rough machining →Shot blasting →Heat treatment →Testing →Fashioning →Cleaning→ Assembly→ Packing→ Shipping

3.Samples Procedure

We could develop the sample according to your requirement and amend the sample constantly to meet your need.

4.Research & Development

We usually research the new needs of the market and develop the new model when there is new cars in the market.

5.Quality Control

Every step should be special test by Professional Staff according to the standard of ISO9001 and TS16949.

♦FAQ

Q 1: Are you trading company or manufacturer?

A: We are a professional manufacturer specializing in manufacturing various series of couplings.

Q 2: Can you do OEM?

Yes, we can. We can do OEM & ODM for all the customers with customized artworks of PDF or AI format.

Q 3: How long is your delivery time?

Generally it is 20-30 days if the goods are not in stock. It is according to quantity.

Q 4: Do you provide samples? Is it free or extra ?

Yes, we could offer the sample but not for free.Actually we have a very good price principle, when you make the bulk order then cost of sample will be deducted.

Q 5: How long is your warranty?

A: Our Warranty is 12 months under normal circumstance.

Q 6: What is the MOQ?

A: Usually our MOQ is 1 pcs.

Q 7: Do you have inspection procedures for coupling ?

A: 100% self-inspection before packing.

Q 8: Can I have a visit to your factory before the order?

A: Sure,welcome to visit our factory.

Q 9: What’s your payment?

A: T/T.

♦Contact Us

Web: huadingcoupling

Add: No.11 HangZhou Road,Chengnan park,HangZhou City,ZheJiang Province,China /* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Understanding the Torque and Misalignment Capabilities of Motor Couplings

Motor couplings play a critical role in transmitting torque from the motor to the driven equipment while accommodating certain degrees of misalignment between the motor and driven shafts. The torque and misalignment capabilities of motor couplings are essential factors to consider when selecting the appropriate coupling for a specific application.

Torque Capabilities:

The torque capacity of a motor coupling refers to its ability to handle the maximum amount of torque that can be transmitted through the coupling without causing failure or damage. Couplings are designed with specific torque ratings to ensure reliable power transmission.

The torque capacity of a motor coupling depends on factors such as the material used, the size and design of the coupling, and the application requirements. High-performance couplings made of robust materials, such as steel or alloy, can handle higher torque loads and are often used in heavy-duty industrial applications.

Misalignment Capabilities:

Misalignment is a common occurrence in mechanical systems due to factors such as installation errors, thermal expansion, and dynamic forces. Motor couplings are designed to accommodate certain degrees of angular, parallel, and axial misalignment between the motor and driven shafts.

The misalignment capabilities of a motor coupling are specified as angular misalignment, parallel misalignment, and axial misalignment. Angular misalignment refers to the angle between the motor and driven shafts, parallel misalignment refers to the lateral offset between the shafts, and axial misalignment refers to the axial displacement along the shafts.

Flexible couplings, such as elastomeric or grid couplings, offer greater misalignment capabilities compared to rigid couplings like gear couplings. The ability to handle misalignment helps reduce stress on the connected equipment and prolongs the life of the coupling and other mechanical components.

Selecting the Right Coupling:

When selecting a motor coupling, it is crucial to consider the torque and misalignment requirements of the specific application. Engineers and designers need to assess the torque demands of the driven equipment and the potential misalignments that may occur during operation.

Choosing a coupling with adequate torque and misalignment capabilities ensures efficient power transmission, minimizes wear on the equipment, and prevents premature failure. Additionally, the coupling’s operating conditions, environmental factors, and service life expectations should be taken into account to make an informed coupling selection.

In summary, understanding the torque and misalignment capabilities of motor couplings is essential for optimal performance, reliability, and longevity in mechanical power transmission systems.

“`

Please answer in detail: Comparing motor couplings with direct drives and other power transmission methods.

Motor couplings and direct drives are two common power transmission methods used in various mechanical systems. Let’s compare these methods with other power transmission approaches:

1. Motor Couplings

Motor couplings are mechanical devices used to connect two shafts and transmit torque from one to the other. They allow some misalignment between the shafts, reducing stress and increasing the lifespan of the connected components. Common types of motor couplings include:

- Flexible Couplings: These couplings are designed to accommodate angular, parallel, and axial misalignments between shafts. They are versatile and offer shock absorption.

- Rigid Couplings: Rigid couplings provide a solid connection between shafts, offering high torque transmission with little to no misalignment allowance.

- Universal Couplings: Also known as Hooke’s joints, universal couplings transmit torque through two intersecting shafts, allowing for misalignment between them.

2. Direct Drives

Direct drives, also known as direct-drive mechanisms, eliminate the need for intermediary power transmission elements like gears, belts, or chains. In this approach, the motor is directly coupled to the driven load, providing a more efficient power transfer. Direct drives offer advantages such as:

- Higher Efficiency: Since there are no intermediate elements, direct drives reduce power losses, resulting in improved overall efficiency.

- Less Maintenance: Eliminating belts or gears reduces the need for maintenance and reduces the chances of mechanical failures.

- Reduced Noise: The absence of gear or belt noise contributes to quieter operation.

3. Other Power Transmission Methods

In addition to motor couplings and direct drives, there are other power transmission methods, each with its own advantages and use cases:

- Gear Transmission: Gears are widely used for torque transmission and speed reduction. They offer precise control but may require regular maintenance.

- Belt and Chain Drives: These systems are cost-effective and offer flexibility in layout design. However, they may suffer from slippage and require tension adjustments.

- Hydraulic Transmission: Hydraulic systems are used in heavy machinery, offering high torque capabilities and smooth operation. However, they require more complex control systems.

- Pneumatic Transmission: Pneumatic systems use compressed air for power transmission, offering clean and lightweight operation.

Choosing the appropriate power transmission method depends on factors such as the application requirements, load characteristics, efficiency, maintenance considerations, and cost constraints.

“`

Comparison between Grid Couplings and Other Types of Flexible Couplings

Flexible couplings are essential components in mechanical power transmission systems, and different types of couplings offer various features and advantages. Here is a comparison between grid couplings and some other common types of flexible couplings:

| Coupling Type | Advantages | Disadvantages | Applications |

|---|---|---|---|

| Grid Couplings |

|

|

|

| Elastomeric Couplings |

|

|

|

| Gear Couplings |

|

|

|

The choice of coupling type depends on the specific requirements of the application. Grid couplings are favored in heavy-duty industrial machinery that requires high torque capacity and misalignment tolerance. Elastomeric couplings are commonly used in general industrial applications where flexibility and damping of vibrations are crucial. Gear couplings find applications in high-speed machinery and equipment. Ultimately, the selection of the right coupling type involves considering factors such as torque requirements, misalignment conditions, operating speed, space constraints, and budget considerations.

“`

editor by CX 2024-03-26