Product Description

Product Description

Product Description

Ever-power specialist in making all kinds of mechanical transmission and hydraulic transmissions like planetary gearboxes, worm reducers, in-line helical gear speed reducers, parallel shaft helical gear reducers, helical bevel reducers, helical worm gear reducers, agricultural gearboxes, tractor gearboxes, auto gearboxes, pto drive shafts, special reducer & related gear components and other related products, sprockets, hydraulic system, vacuum pumps, fluid coupling, gear racks, chains, timing pulleys, udl speed variators, v pulleys, hydraulic cylinder, gear pumps, screw air compressors, shaft collars low backlash worm reducers and so on. Furthermore, according to customers’ drawings, we can produce customized variators, geared motors, electric motors, and other hydraulic products.

The company provides a reliable product quality guarantee through advanced inspection and testing equipment, a professional technical team, exquisite processing technology, and a strict control system.

The company has been developing rapidly in recent years because of its rich experience in production, advanced management system, standardized management system, and strong technical force. We always adhere to the concept of survival by quality and development by innovation in science and technology.

Ever-power Group is willing to work with you hand in hand and create brilliance together!

Material available |

Surface treatment |

Heat treatment |

|

Low carbon steel, C45, 20CrMnTi, 42CrMo, 40Cr, stainless steel. Can be adapted regarding customer requirements. |

Blacking, galvanization, chroming, electrophoresis, color painting, … |

High frequency quenching heat treatment, hardened teeth, carbonizing, nitride, … |

Our Factory

Application – Photos from our partner customers

Company Profile

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Is it Possible to Replace a Motor Coupling Without Professional Assistance?

Replacing a motor coupling can be a relatively straightforward task, and it is possible to do it without professional assistance, depending on your level of mechanical skill and experience. However, it is essential to exercise caution and follow proper procedures to ensure a successful replacement and prevent any potential damage.

If you have a basic understanding of mechanical systems and tools, you can attempt to replace a motor coupling by following these general steps:

- Turn Off Power: Before starting any work, make sure to turn off the power supply to the motor to prevent accidents.

- Access the Coupling: Locate the motor coupling, which connects the motor shaft to the driven shaft or load. It is often situated near the motor or at the input of the driven equipment.

- Remove Guards and Covers: If applicable, remove any guards or covers that may be concealing the coupling and motor assembly.

- Loosen Fasteners: Loosen and remove the fasteners, such as set screws or bolts, that secure the coupling halves to the motor and driven shafts.

- Remove Old Coupling: Carefully slide or separate the old coupling from the motor and driven shafts.

- Install New Coupling: Place the new coupling onto the motor and driven shafts, ensuring proper alignment and engagement.

- Tighten Fasteners: Securely tighten the fasteners to hold the new coupling in place.

- Check Alignment: Verify that the motor and driven shafts are aligned properly to prevent premature wear and damage to the new coupling.

- Replace Guards and Covers: Once the new coupling is installed and aligned, replace any guards or covers that were removed.

- Turn On Power: After completing the replacement, turn the power supply back on and test the motor and driven equipment for proper operation.

While the process seems straightforward, it is essential to refer to the specific instructions provided by the manufacturer of the motor and coupling. Some couplings may have unique installation requirements, and following the manufacturer’s guidelines ensures optimal performance and safety.

If you are unsure about any aspect of the replacement process or encounter difficulties during the procedure, it is recommended to seek assistance from a qualified professional or a trained technician to avoid any potential damage to the motor or equipment.

“`

Do motor couplings require regular maintenance, and if so, what does it involve?

Motor couplings do require regular maintenance to ensure their proper functioning and to extend their lifespan. The maintenance procedures typically involve the following steps:

- Inspection: Regular visual inspections are necessary to check for signs of wear, damage, or misalignment. Inspect the coupling for any cracks, corrosion, or unusual vibrations.

- Lubrication: Some motor couplings, especially flexible and universal couplings, require proper lubrication to reduce friction and prevent premature failure. Follow the manufacturer’s recommendations for the type and frequency of lubrication.

- Tightening: Check and tighten the coupling’s fasteners regularly to prevent any loosening that might occur due to continuous operation or vibrations.

- Alignment: Ensuring proper alignment between the motor and driven load is essential for motor couplings. Misalignment can lead to increased stress and wear on the coupling, causing it to fail prematurely.

- Replacement: Over time, motor couplings may experience wear and tear, especially in high-load or high-speed applications. Replace the coupling if it shows significant signs of wear, deformation, or damage that could affect its performance.

- Balancing: In some cases, dynamic balancing of the coupling may be necessary to avoid vibration issues, which could lead to equipment failure or reduced efficiency.

By conducting regular maintenance, you can detect potential issues early and prevent costly breakdowns or production downtimes. It is essential to follow the manufacturer’s guidelines and recommendations for maintenance to ensure optimal performance and longevity of the motor couplings.

“`

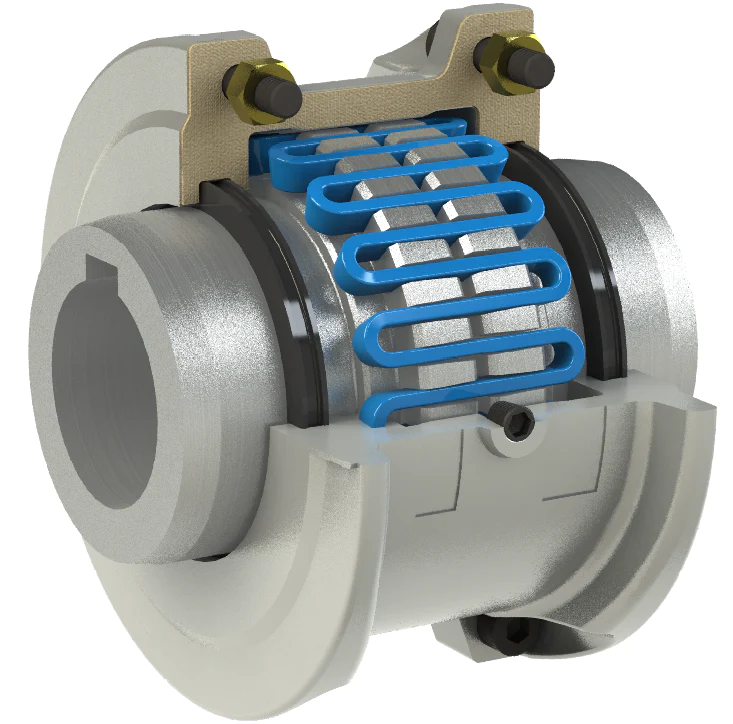

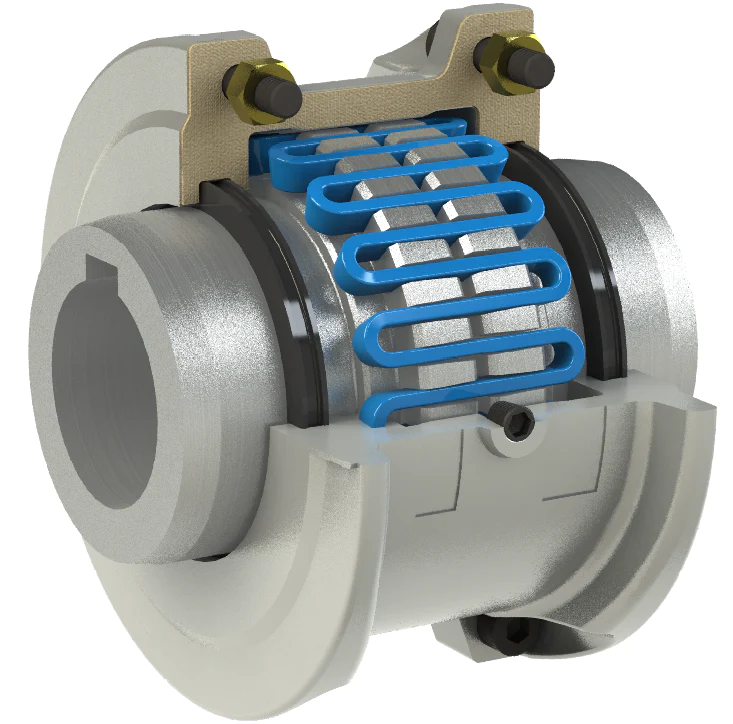

Advantages of Using Grid Couplings in Industrial Machinery and Equipment

Grid couplings offer several advantages in industrial machinery and equipment applications, making them a popular choice for power transmission systems. Some of the key advantages include:

- High Torque Capacity: Grid couplings have a high torque capacity, allowing them to transmit significant amounts of torque between shafts. This makes them suitable for heavy-duty industrial applications that require substantial power transmission.

- Misalignment Tolerance: One of the primary benefits of grid couplings is their ability to accommodate misalignments between the connected shafts. They can handle both angular and radial misalignments, reducing stress on the machinery and extending component life.

- Vibration Damping: The serrated grid element in grid couplings acts as a vibration damper, absorbing shocks and vibrations that can occur during operation. This feature helps in reducing noise levels and ensuring smoother machinery performance.

- Shock Load Absorption: Grid couplings are designed to absorb shock loads, which are common in industrial environments. This capability protects the connected equipment from sudden overloads and prevents damage to the machinery.

- Torsional Flexibility: The flexible grid structure of the coupling provides torsional flexibility, allowing it to compensate for torsional vibrations and torque spikes. This feature contributes to improved system stability and reduced stress on components.

- Easy Installation and Maintenance: Grid couplings are relatively easy to install, making them a convenient choice for machinery assembly. They also require minimal maintenance, resulting in cost savings and reduced downtime for equipment servicing.

- Wide Range of Applications: Grid couplings are versatile and suitable for various industries, including mining, pulp and paper, steel mills, and power generation. They are employed in pumps, compressors, fans, conveyors, mixers, and other industrial equipment.

- Cost-Effective: Considering their durability, misalignment tolerance, and low maintenance requirements, grid couplings offer a cost-effective solution for power transmission needs in industrial settings.

Overall, grid couplings provide a robust and reliable means of transmitting power between rotating shafts while protecting machinery from adverse conditions. Their ability to handle misalignments and dampen vibrations makes them a valuable component in a wide range of industrial applications.

editor by CX 2024-05-09